Damp-proof doors

Damp-proof doors

Design according to DIN 68706 part 1:

The doors with a thickness of approx. 40 mm are made of multi-layer composite panels. These are suitable for use in rooms with increased humidity and low splash water exposure.

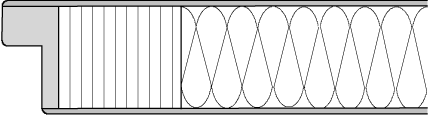

K 42 TF

Frame:

3-sided natural fibre board approx. 50 mm, bottom 50 mm PU recycling panels, 100 % water-resistant

Inner layer:

36 mm solid plastic rigid foam

Topcoat:

2.0 mm high pressure laminate according to DIN EN 438, waterproof gluing with 2-comp. adhesive

Edges:

Blunt or with standard rebate to DIN 18101, 3-sided solid plastic frame can be planed (colours: white, grey, black, beige or ivory)

Edging band drilling / milling and lock milling always included in the door panel price!

Door leaf can be shortened up to 30 mm, also with special sized doors!

Also available as a sliding or double-action door at the same price.

|

| Stress group M | ∎ |

| Stress group S | ● |

| Stress group E | ● |

| Climate class I | ∎ |

| Climate class II | ● |

| Climate class III | ● |

| Sound insulation I (RW, P32dB) | ● |

| Sound insulation II (RW, P37dB) | ● |

| Sound insulation III (RW, P42dB) | ● |

| double wing doors | ● |

| Class S frame reinforcement | ● |

| Reinforcement for overhead door closer, handles and stopper | ● |

| 4-sided solid plastic frame | ● |

| Ventilation grille, special milling | ● |

| Light cut-outs/ Portholes | ● |

| Double sealing | ● |

| Lock milling | ∎ |

| Milling / Drilling edging bands | ∎ |

| 3rd edging band milling / drilling | ● |

| 2nd lock milling | ● |

| Special milling e.g. integrated door closers / 3-fold locking etc. | ● |

| Lead inserts for X-ray rooms | ● |

| Door thickness 50 mm / 70 mm | ● |

| Seam revealed | ● |

| Double rebate (from door thickness 50mm) | ● |

| Top panel | ● |

| Door leaf with or without edge | ● |

- Max. door height 3.900mm, max. door width 1.480mm (depending on laminate or HPL availability with or without joint line)

- ∎ Standard ● Optional

Economy

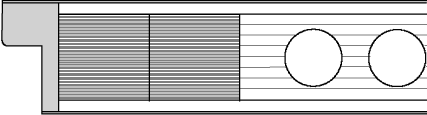

Frame:

3-sided natural fibre board approx. 50 mm, bottom 50 mm PU recycling panels, 100 % water-resistant

Inner layer:

38 mm tubular chipboard

Topcoat:

2.0 mm high pressure laminate according to DIN EN 438, waterproof gluing with 2-comp. adhesive

Intermediate layer:

3-4 mm natural fibre board

Edges:

Blunt or with standard rebate according to DIN 18101, 3-sided solid plastic frame can be replaned (colours: white, grey, black, beige or ivory)

Edging band drilling / milling and lock milling always included in the door panel price!

Door leaf can be shortened up to 30 mm, also with special sized doors!

Also available as a sliding or double-action door at the same price.

|

| Stress group M | ∎ |

| Stress group S | ∎ |

| Stress group E | ● |

| Climate class I | ∎ |

| Climate class II | ∎ |

| Climate class III | ● |

| Sound insulation I (RW, P32dB) | ● |

| Sound insulation II (RW, P37dB) | ● |

| Sound insulation III (RW, P42dB) | ● |

| double wing doors | ● |

| Class S frame reinforcement | ● |

| Reinforcement for overhead door closer, handles and stopper | ● |

| 4-sided solid plastic frame | ● |

| Ventilation grille, special milling | ● |

| Light cut-outs/ Portholes | ● |

| Double sealing | ● |

| Lock milling | ∎ |

| Milling / Drilling edging bands | ∎ |

| 3rd edging band milling / drilling | ● |

| 2nd lock milling | ● |

| Special milling e.g. integrated door closers / 3-fold locking etc. | ● |

| Lead inserts for X-ray rooms | ● |

| Door thickness 50 mm / 70 mm | ● |

| Seam revealed | ● |

| Double rebate (from door thickness 50mm) | ● |

| Top panel | ● |

| Door leaf with or without edge | ● |

- Max. door height 3.900mm, max. door width 1.480mm (depending on laminate or HPL availability with or without joint line)

- ∎ Standard ● Optional